Electric Tool Maintenance

RUPES tools are engineered and built to provide years of hassle-free use, but there are some basic maintenance items and things to avoid to ensure that your polisher stays in peak operating condition.

- Clean debris, dust, from the housing regularly by blowing the tool off with compressed air or vacuuming it out of the vents.

- Inspect backing plates for wear, warping, or damage before each use. Replace damaged backing plates immediately.

- Inspect and tighten backing plate attachment bolts before each use.

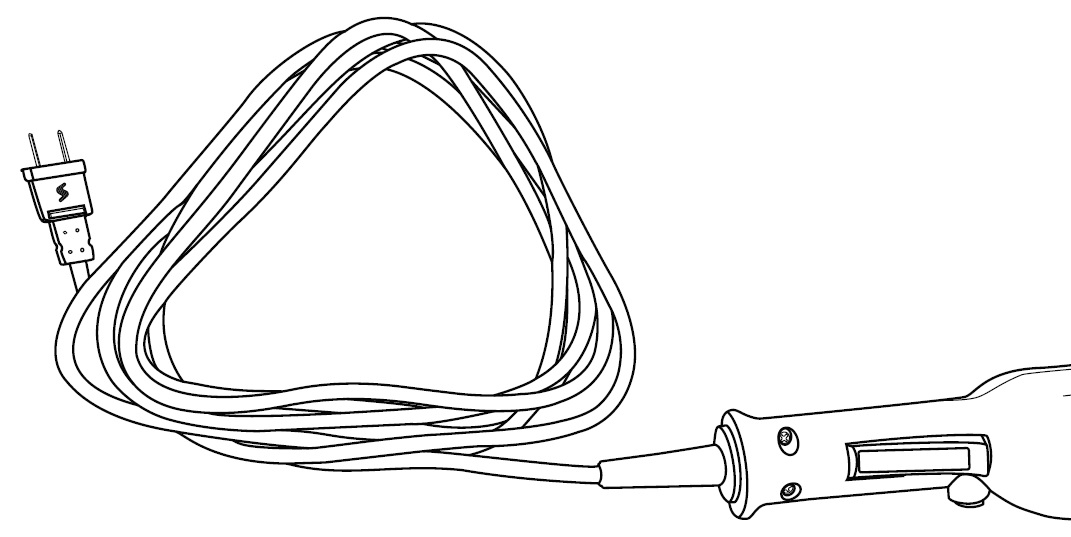

- Inspect the cord for cuts, tears, or other damage that could expose the internal wiring.

- See special instructions for shroud lubrication and cord care below:

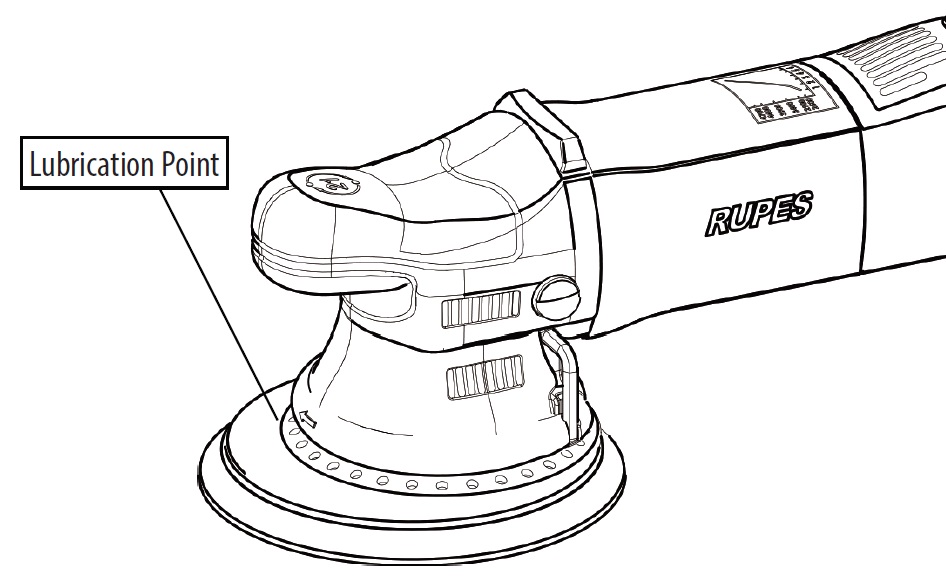

SHROUD LUBRICATION:

To maintain optimal performance it may be necessary to periodically apply a small amount of dielectric lubricant to the backing plate at the point it contacts the rubber shroud. Spread a small amount of dielectric lubricant on top of the backing plate and rotate a few times by hand before operating the tool. For tools that are operated daily lubrication may be required monthly.

CORD MANAGEMENT:

The cord of your electric tool should always be coiled in large, loose, loops. Wrapping the cord tightly around the body of the tool can result in premature cord failure. Never use the cord for carrying, pulling, or unplugging the power tool. Keep cords away from heat, oil, sharp edges or moving parts.

Connect With Us