LHR15 and LHR21 Mark V Polishers

Engineered for Noise Reduction and Minimal Vibration

The LHR Mark V facilitates high-quality finishes using fewer steps. Engineered with a focus on reducing noise and minimizing vibrations, it incorporates our innovative Polysynthec gear system and the latest PrecisionPro backing plate to elevate both performance and precision.

NEW GEAR SYSTEM

Powered by the most advanced POLYSYNTHEC™ solutions, The new advanced gears are meticulously designed to reduce noise levels during polishing operations. With a focus on reducing vibrations, the new gears deliver exceptional stability and precision, enabling you to maintain complete control over your polishing movements.

NEW ONE-BLOCK COVER

The one-bloak construction of the cover head ensures maximum stability, eliminating any potential movement or flexing that can compromise your polishing results. The new cover is engineered to significantly reduce vibrations, providing a comfortable and stable grip, allowing you to focus on achieving flawlessly polished surfaces

NEW VENTILATION SYSTEM

New advanced airflow engineering to optimize ventilation, effectively reducing heat buildup during prolonged polishing sessions. The new ventilation system maximizes cooling efficiency, keeping the Mark V polisher at an ideal operating temperature. It minimizes stress on internal components, ensuring longevity and reducing the risk of malfunctions.

NEW ECCENTRIC SET

Redesigned for enhanced efficiency and user comfort, it boasts a more compact form, simplifying handling and maneuverability during operation. The improved design also places a strong emphasis on vibration reduction, delivering a smoother and more comfortable experience that ensures precision and control throughout each task.

NEW ANTI-SPINNING RING

Experience unparalleled precision, durability, maneuverability, and cutting capacity with this innovative feature. Benefit from reduced friction and heat, enabling effortless operation and extended usage. Seamlessly tackle any surface with enhanced rotation, unlocking limitless possibilities for flawless results.

PRECISIONPRO PAD

NEW GEARS IN RUPES POLYSYNTHEC™ MATERIAL

New gears in RUPES Polysynthec material are a critical innovation in the design of the new polishers, offering a range of benefits that enhance the tool’s performance and user experience. These advanced gears are engineered from high-quality materials, providing exceptional durability and efficiency.

Durability and Wear Resistance: Gears in Polysynthec are engineered to resist wear and impact, offering a long-lasting and reliable performance even under demanding conditions.

Noise Reduction: The materials used in Polysynthec gears naturally dampen vibrations, leading to quieter operation by reducing gear noise and minimizing the sound of meshing gears.

Reduced Weight: These gears are much lighter than metal alternatives, which reduces the overall weight of the polisher, making it easier to handle and maneuver, especially during prolonged use.

Enhanced Efficiency: Polysynthec gears operate with lower friction, leading to smoother performance, reduced energy loss, and consistent speed and torque delivery.

Smooth Operation: Polysynthec gears require less lubrication due to their low friction properties and precise molding, which results in smooth gear engagement and minimal maintenance.

Thermal Stability: These gears maintain their performance across a range of temperatures, preventing overheating and ensuring reliable operation.

REDUCED VIBRATIONS

Reducing vibrations significantly elevates the tool’s performance and usability. Lower vibrations lead to enhanced user comfort, improved control, and more consistent polishing results. This refinement minimizes arm fatigue, extends the life of the polisher, and ensures a quieter, safer operation. By addressing the vibration issue, modern polishers deliver a smoother, more effective polishing experience.

Enhanced Comfort: Lower vibration significantly reduces hand and arm fatigue, allowing users to operate the polisher comfortably for extended periods without experiencing the strain or discomfort associated with prolonged tool use.

Increased Safety: Less vibration reduces the chance of the polisher slipping or moving unexpectedly, enhancing safety by ensuring the tool remains stable in the operator’s hands, especially when working on vertical or angled surfaces.

Health Benefits: By significantly reducing tool vibrations, the polisher minimizes the potential for long-term health issues related to extended use. This enhancement promotes better overall well-being and ensures a safer, more comfortable user experience over prolonged periods.

Better Polishing Results: Minimizing vibration reduces the likelihood of pad skipping and bouncing on the surface, which leads to a smoother, more uniform finish. This results in a professional-grade polish with fewer imperfections.

Extended Tool Life: By decreasing the mechanical stress and wear on the internal components, reduced vibration contributes to the longevity of the polisher. Components experience less friction and impact, which reduces maintenance needs and extends the tool’s lifespan.

NOISE REDUCTION BY 47%

Noise reduction brings significant advantages that enhance the user experience and improve tool performance. By minimizing operational noise, these advanced polishers protect hearing and create a more comfortable working environment.

Improved Comfort: Quieter operation reduces auditory strain, enhancing user comfort. This makes the polishing process more pleasant and sustainable, especially for extended sessions. Users can work longer without noise-induced fatigue.

Improved Tool Handling: Noise reduction makes the polisher feel smoother and less aggressive, enhancing handling and control. This is beneficial not only for professionals but also for beginners or those less experienced with polishing, as it provides a more user-friendly experience and reduces the intimidation factor of the tool.

Reduced Disturbance: With quieter operation, polishers are less likely to disturb others, making them ideal for use in noise-sensitive environments such as residential areas, shared workspaces, or indoors.

Lower Vibration: Noise reduction often correlates with reduced vibrations, which further enhances user comfort and extends the life of the tool. Less vibration means lower wear and tear on the polisher, contributing to longer service intervals and reduced maintenance costs.

Higher efficiency: a lower level of noise and vibrations means that all the energy we take from the plug and that we pay at the end of the month in the energy bills, is used for actually polishing and not dispersed in counterproductive disturbing side effects.

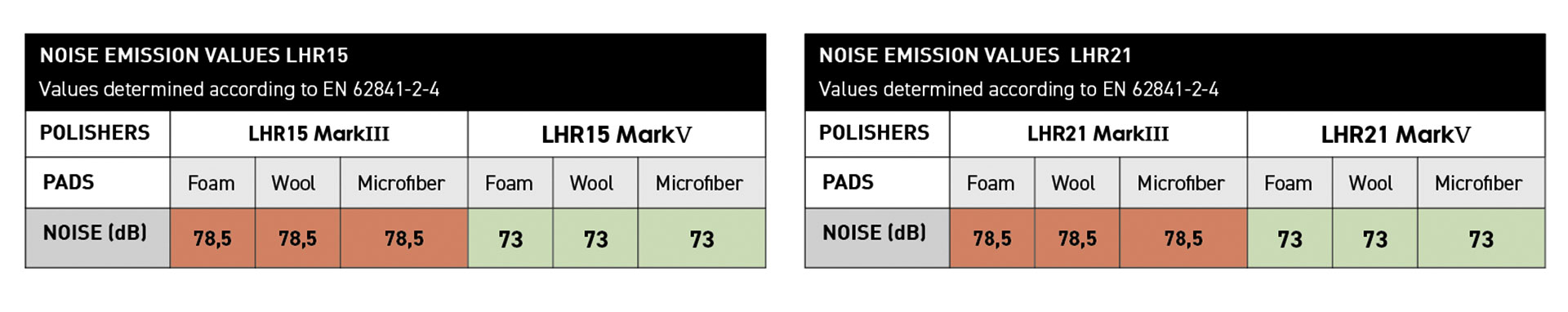

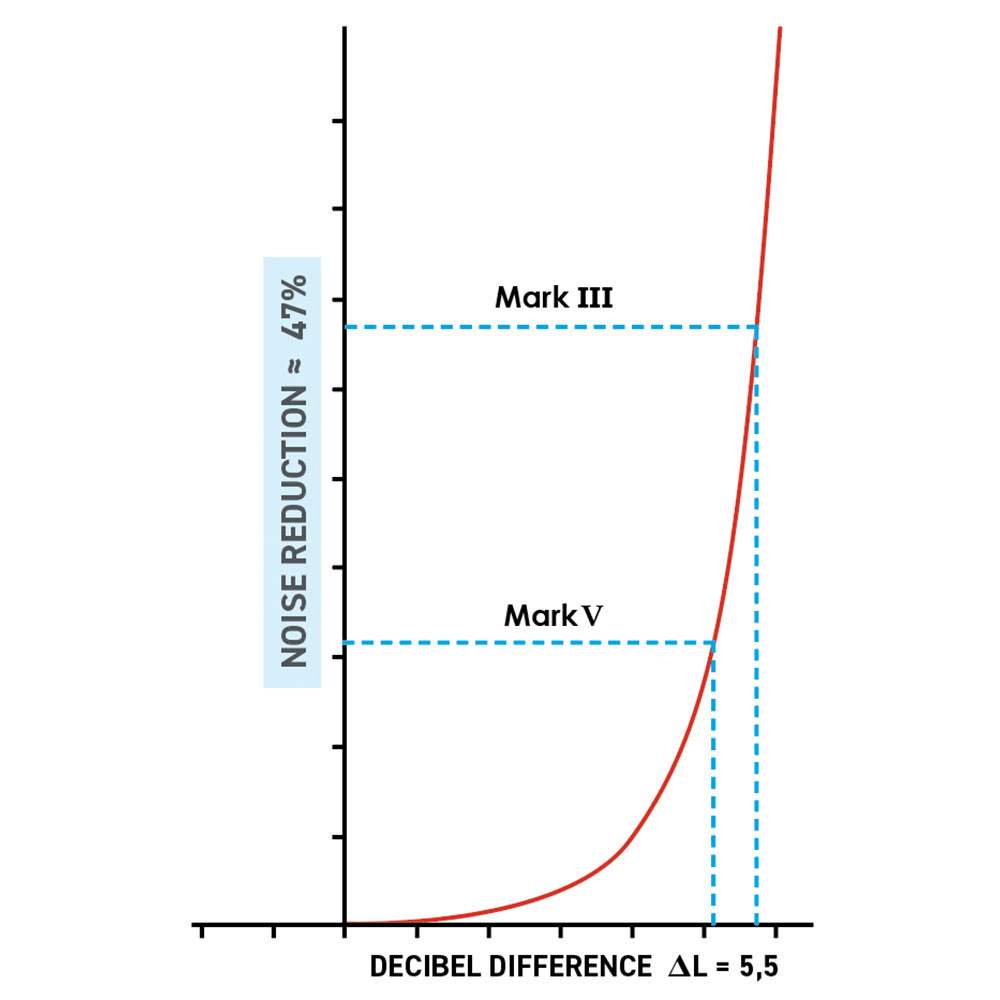

TECHNICAL DETAILS ON NOISE REDUCTION

Reducing noise levels from 78,5 decibels (dB) to 73 dB is a significant improvement in the acoustic performance of a device, such as a dual action polisher where noise levels are a concern for user comfort and safety. This reduction, although it may seem small numerically, represents a substantial decrease in perceived noise. The decibel scale is logarithmic, not linear, therefore, a 5,5 dB reduction means in about a 47% reduction in perceived loudness, so the noise is significantly less noticeable and less intrusive to users.

NOISE REDUCTION CALCULATION FROM MarkIII TO Mark V

The sound pressure level (SPL) can be calculated and interpreted to understand the effectiveness of noise reduction.

The decibel (dB) scale is logarithmic, so a reduction in dB corresponds to a significant decrease in sound intensity and the formula to calculate sound pressure level (SPL) in decibels is:

CONCLUSION

The reduction of noise from 78,5 dB to 73 dB in a dual action polisher, achieved through advanced engineering and design, results in a sound pressure decrease of approximately 47%. This significant reduction enhances user comfort, safety, and overall tool performance, providing a much quieter and more efficient polishing experience.

LOWER CENTER OF GRAVITY

Reduced height and lower center of gravity by ~10% for superior stability and control

TECHNICAL DATA

LHR21 | LHR15 | ||

Ø backing pads | mm-in | 150 - 6” | 125 - 5” |

Ø orbit | mm-in | 21 - 13/16” | 15 - 19/32” |

Power | Watt | 500 | 500 |

R.P.M. | 3000 - 4500 | 3000 - 5200 | |

Weight | kg-lbs | 2.7 - 5.95 | 2.6 - 5.73 |

Speed control | • | • | |

Backing pad thread | M8-F | M8-F | |

Electrical cord | m-ft | 9 – 30’ | 9 – 30’ |

PrecisionPro BACKING PLATE

These revolutionary backing pads have been meticulously designed to take your polishing experience to the next level.

Without polyurethane, they not only bring durability to the forefront but also provide a lower center of gravity.

This means enhanced stability during operation, allowing for greater control and precision in your work.

The rubber edge adds an extra layer of finesse to your polishing tasks, ensuring that even the most delicate surfaces are treated with care. What truly sets our backing pads apart is their ability to guarantee better balancing, even with different polishing pads. This means you can effortlessly switch between various pads without compromising on performance or quality.

Lower Center of Gravity

For superior stability and control

Rubber Border Protection

For added surface protection and a smoother glide

Balancing Versatility

Perfect balance with various polishing pads

EXCLUSIVE 5-YEAR EXTENDED WARRANTY

RUPES’ professional tools are renowned for their durability and performance, and now, with the RUPES Mark V Polishers, you can enjoy even greater peace of mind. While our standard one-year warranty covers professional users, we’re excited to offer an exclusive opportunity to extend your warranty to a total of 5 years!

How to Get Your 5-Year Warranty: Simply register your RUPES MarkV Polisher within 30 days of purchase, and you’ll receive an extended warranty that ensures your investment is protected for 5 full years.

What’s Covered: RUPES will provide comprehensive warranty service at no charge to you, covering defects in materials and workmanship during production. This warranty is exclusively available to the original end-user purchaser, ensuring you receive the quality and service you deserve.

Connect With Us