These All-New Compounds Are More Than Just Pretty Packaging

Using the latest breakthroughs in abrasive technology, developed, tested, refined, blended, and packaged 100% in-house by RUPES in Italy, these all-new compound and polish formulas aren’t just a new standard for RUPES, they’re a new standard for the industry. Each of these new BigFoot liquids represent the RUPES commitment to innovation and quality. Improved cutting performance, astounding finishing ability, and a focus on the user experience we are confident that the new BigFoot D-A Compounds and UNO Pure will become staples in your arsenal for paint correction. Available in select markets now and at US distributors this Summer!

BIGFOOT D-A COARSE HIGH-PERFORMANCE POLISHING COMPOUND

Simply a new standard. This all-new, high performance, polishing compound has been formulated by RUPES to expand your expectations for what a coarse compound can do. More defect removal? Check. A better finish? Absolutely. Less dusting? Effortless wipe off? Even easier to use? Yes, yes, and yes! BigFoot D-A COARSE offers incredible performance on all orbital polishers; Gear-Driven and Random Orbital.

- High-performance polishing compound removes defects and sand scratches up to 1500 grit quickly

- Durable lubrication system for an extended polishing cycle and longer working time

- The low-dusting formula reduces post-compound cleanup work

- One-step moderate-to-severe defect removal and finishing on most paints

- Offers one-step cutting-and-polishing ability on most paints

- Formulated specifically for use on all random orbital or gear-driven orbital polishers

BIGFOOT D-A FINE HIGH-PERFORMANCE POLISHING COMPOUND

The result of extensive testing to develop a fine polish that combines noticeable cutting performance with impressive finishing capability. The proprietary formula developed and blended in-house by RUPES is designed to perform with both large stroke random orbital polishers and gear-driven orbital polishers. When combined with RUPES specially designed yellow foam, wool, or microfiber pads DA-FINE delivers a much higher level of defect removal when compared to traditional fine polishing compounds. More cut, yet still provides the incredibly high finish quality and easy wipe off expected from a product formulated for final finishing after a coarse cutting compound. BigFoot D-A FINE HIGH-PERFORMANCE POLISHING COMPOUND is body shop safe and performs well on clear coat, single-stage paint, gelcoat, varnish, and more.

- Excellent cutting performance relative to most “fine” polishing compounds

- New micro-abrasive technology and proprietary blend enhances finishing ability

- Easy wipe-off, for fewer towel marks on soft paints or delicate surfaces

- Easy application when used with RUPES color-coordinated pad system

- One-step light defect removal and finishing on most paints

- Can also be an excellent 2nd step polish following D-A Coarse Compound

- Recommended for use with BigFoot Random Orbital or Gear-Driven tools

UNO PURE UNIVERSAL ULTRA FINISHING POLISH

UNO PURE is a universally compatible, ultra-fine abrasive polish designed for use on all tool types, including Rotary, Random Orbital, or Gear-Driven Orbital. The proprietary formula developed and blended in-house by RUPES, uses the latest in abrasive technology to produce the highest possible optical clarity and reflectivity when used with RUPES BigFoot polishing system tools and pads. UNO PURE is ideal for very soft or haze-prone paints and can be used in jeweling applications to create a show car finish, even on dark colors. The absence of fillers, ease of use, easy wipe-off ensure the best user experience. The body shop safe formulation makes it the ideal solution for a variety of applications.

- Universal across all BigFoot Polishing System tool movements, including orbital, gear driven, and rotary.

- Smooth user experience with easy wipe off

- Unmatched finishing quality, even on the softest paint systems

- Validated for all paint types, including single-stage, clearcoat, hard, soft, or “sticky” paints

- Versatile applications, simply change the pad to change the performance

- No intentional filling ingredients added

- No protection properties, leaves the finish “PURE” and ready for application of a protective product

- For best results, use with RUPES Ultrafine White Finishing Foam Pads

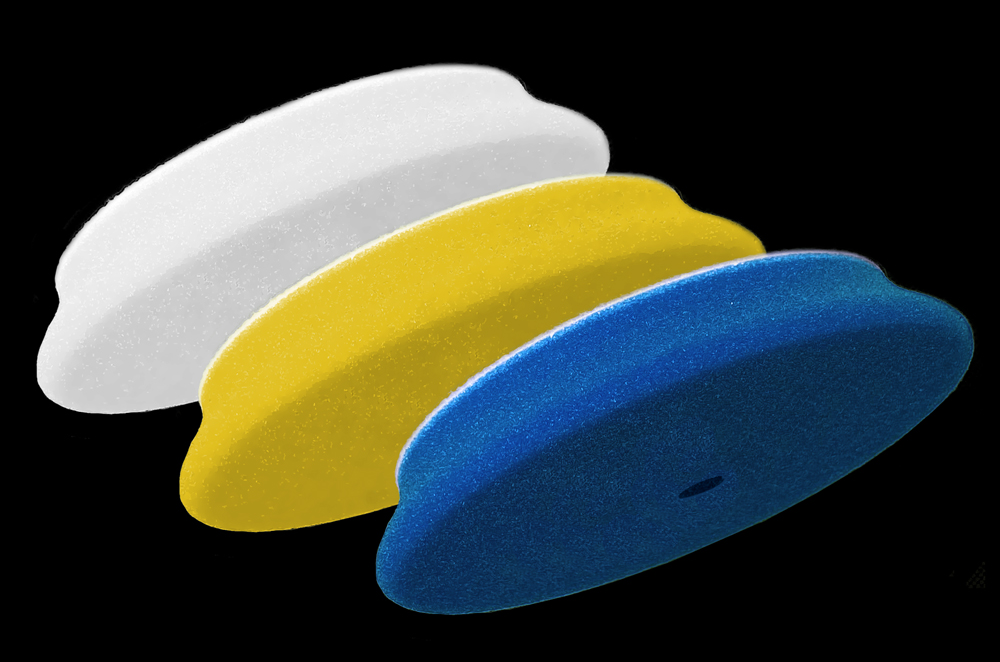

Every Aspect of the Foam Polishing Pad, Carefully Considered

The foam pad is an integral part of the overall performance of any polishing system, especially orbital. The RUPES development team has spent countless hours in the development and testing of all aspects of new D-A FOAM PADS to ensure the most balanced performance, proper heat management, contouring, and versatility. Even the packaging has been developed specifically to protect the foam from UV exposure and degradation. The all-new BigFoot D-A FOAM PADS are constructed using new, proprietary foam formulas and maximized for performance on both large stroke random orbital tools and gear-driven orbital tools. Every pad is carefully designed, manufactured, and packaged entirely in-house by RUPES in Italy to our extremely high quality standards.

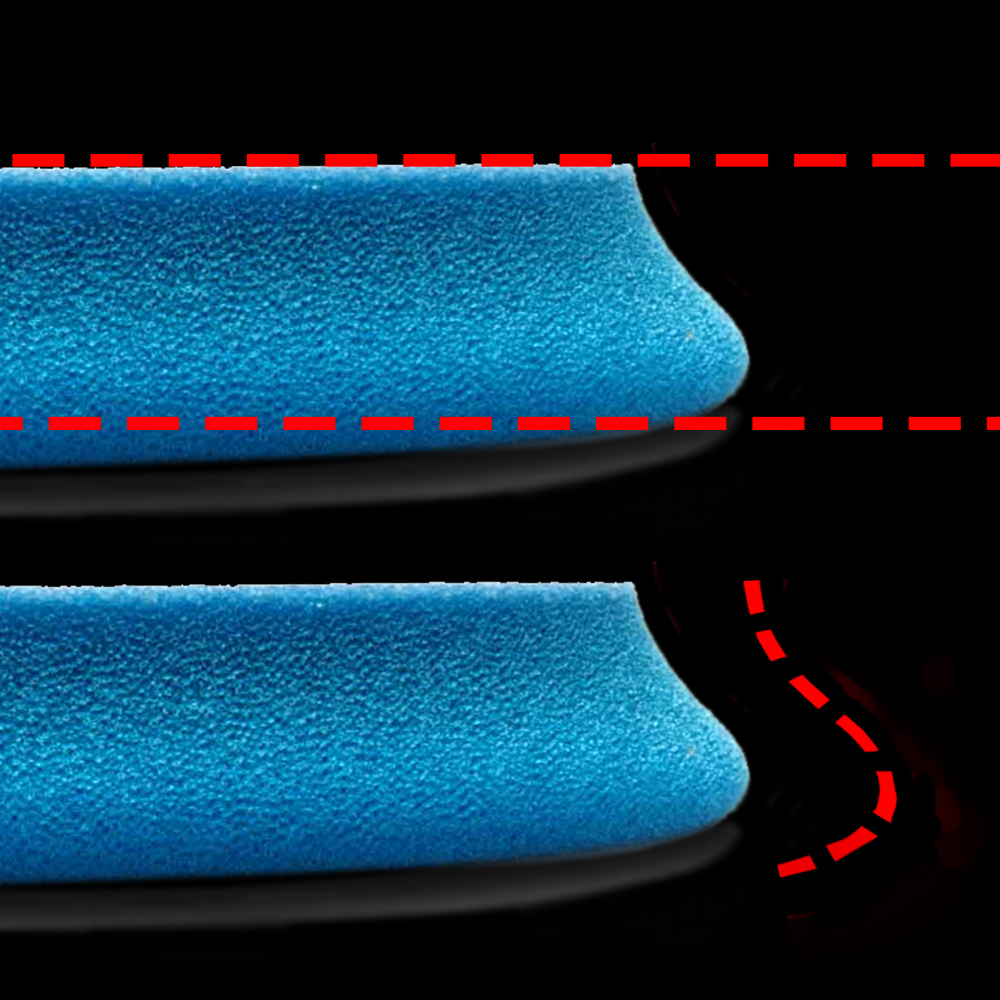

LOWER PROFILE

In addition to all-new materials the new D-A System Foam Pads feature a reduced pad height versus the previous generation BigFoot Random Orbital Pads. In conjunction with the new materials this new height has been extensively tested to provide improved stability and allows the D-A Foam Pads to work on both large stroke random orbital tools and gear-driven tools like the BigFoot Mille.

CONTOUR EDGE

The new, unique, contour edge improves pad stability and provides additional control in the curves. This edge shape will be featured on all 3 grades of D-A Foam Pads and in 180mm, 150mm, and 100mm pad sizes.

MORE THAN PACKAGING

The new metallic film flow pack of the D-A Series Foam Pads offers superior protection against accidental rips or piercing to keep your pads as clean as possible until they’re ready for use. The flow pack also prevents UV exposure to maintain the original integrity of the material regardless of where it is stored or how long it remains packaged before use. Clear plastics commonly used in other pad packaging leaves the pads vulnerable to UV damage.

Sitemap

Contact Us

We are located at:

531 S Taylor Ave,

Louisville, CO 80027

General information:

info@rupesusa.com

Sales & Customer Service:

orders@rupesusa.com

Marketing & Media Inquiries:

marketing@rupesusa.com

Connect With Us